Skis getting slower? Bases scratched up? Not taking or holding wax? We are offering free ski base analyses that can help determine if your skis need a stone grind. Nearly all skis can be improved by a fresh stone grind, even if they have been ground previously. Our ski base analysis can help you determine just how much difference a new grind can make.

The reason that grinding and routine base maintenance are so important lies in their material properties. Due to its ideal material characteristics, ski bases are made from UHMWP, Visit Wikipedia Article. One of the few drawbacks of UHMWP, however, is its relatively low melting point of 130C. For reference, the vast majority of glide waxes have melting points higher than this; only yellow waxes really fall much below the 130C melting point. Because of this discrepancy, any use of high melt point waxes (fluoros and green parafins) is almost certainly going to result in some amount of “seal/burn” occur on your bases. The damage is generally very minor for one or two applications, but can add up over the course of even a single season. Skis that are sealed do not accept wax and will simply not be as fast.

In ski-mad Norway, most master ski racers have their entire ski fleet ground yearly to maintain top performance and extend the life of the ski. At the World Cup level, skis are reground multiple times a season. Importantly, a well maintained ski requires much less base material to be removed during the grinding process, which means that ironically the more frequently a ski is ground, the more times it can be ground before the base material is exhausted. Extremely well cared for skis have been known to be ground as many as 40 times, though such longevity requires ideal circumstances and is rare.

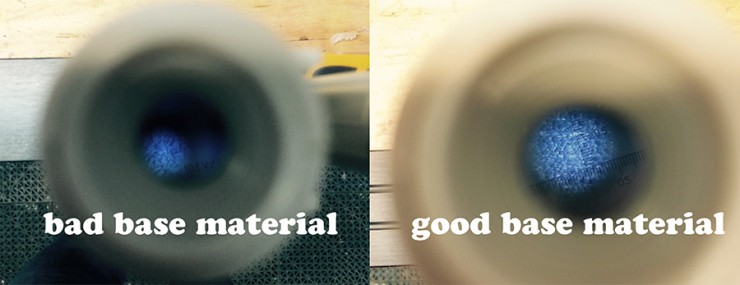

At Gear West, we have the tools to look at base material and show you if your base is sealed or not. Contrary to popular belief, metal brushing will not “open” sealed base material. The only thing you can do to remove the burned layer of sealed base material is steel scraping or stone grinding. Steel scraping, even when done by a skilled technician, leaves no structure behind and thus results in a suboptimal running surface for nearly all conditions. A reliable and race-proven structure from a dedicated Nordic grinding machine will not only open the base, but tune your skis to optimally balance wet and dry friction for whatever conditions you ski in. Below is an example of “open” base material that will be fast and accept wax and “sealed” base material. There are subtle differences but notice the healthy base has a higher density of pores that look more 3D while the sealed base has a mashed/flatter look with less visible pores.

At Gear West we provide the best in stone grinding service. We offer simple yet proven World Cup structures that offer high speed in a wide range of conditions. Our new Tazzari machine cuts precisely, to the level of 1/1000mm. Worried you’ll need to “ski your skis in”? Jan Guenther and Matt Liebsch both raced to 10th place at the 2015 Birkie on brand new stone grinds with absolutely zero kms on them.

http://xcski.gearwest.com/blog/salomon-carbon-skate-lab/1068

Learn more about Tazzari and Gear West stone grinding:

http://www.gearwest.com/tazzari-q-and-a

http://service.gearwest.com/category/stone-grind-service/400465/393873/1306729