How to have fast skis ALL THE TIME and in EVERY CONDITION

I love my job. The contact that I have with people in the ski community is pretty much always positive and enjoyable. We have great waxes and other products so of course generally interaction, feedback, and my motivation are very positive. However sometimes at events or otherwise, I have people approaching me trying to get me to guarantee super fast skis if they use a certain wax. A fairly rare thing is also that a person didn’t have the fast skis that they were hoping for. It is important to take a step back and take an overview so you all have the proper perspective on what makes a fast ski on any particular day.

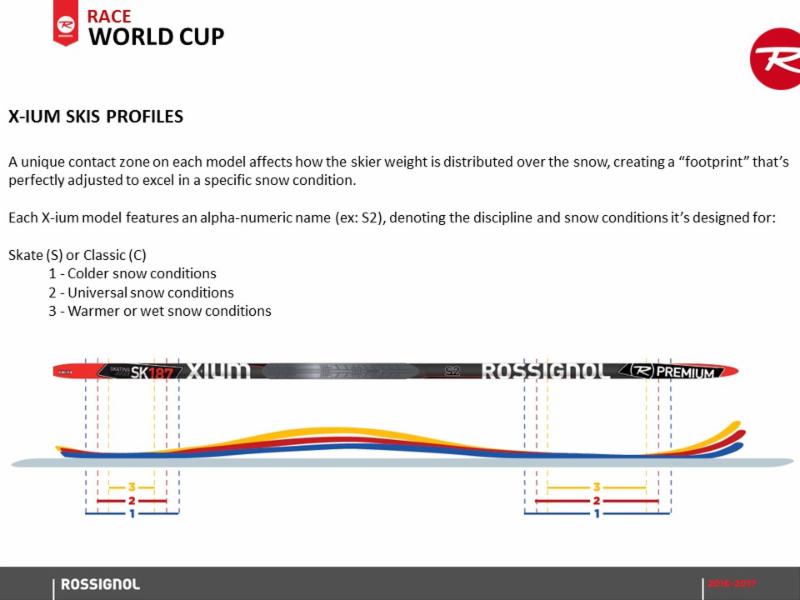

The 3 main factors to having fast skis are ski flex and design, structure, and wax. You could throw base material in there too, but most people have what they have, so that is more of a World Cup level topic. (Note that many skis have different base material that matches the type of conditions that they were designed to ski in, so this is addressed in the ski selection process. Example: Rossignol S3 or C3 have a “wet” clear base material to match the flex and structure that the skis come with).

Far and away, the most important factor in having fast skis are the skis themselves. Given a particular condition, the skis need to match the condition in terms of their flex and design as well as match the skier (weight and ability).

Let me use Rossignol as an example because I am very familiar with them and confident in them. Below is a quick chart explaining the flex/design of the top Rossignol skating skis, the Xium Premium S1, S2, and S3 skis. In each of these skis, the camber height is different as is the contact area of the skis to the snow if the skis are fitted properly. (The concepts are identical for Skate and Classic skis).

If snow is cold, dry, and slow snow, a fast ski will generally have a low camber and a relatively long area of contact in the tip and tail sections. Assuming the structure and wax are “cold”, the skis should be good assuming they are fitted correctly. If the skis have a high camber and a short area of contact in cold, dry, and slow snow, the wax and structure can still slow the skis down further, but the skis will not be very good regardless of how optimal the other two factors are.

It is the same in wet snow. Clearly, having a low camber and more contact between the ski base and the snow will result in more suction and more opportunity to pick up dirt creating more friction and more suction. Minimizing the contact results in much faster skis for the short term and especially after some kms are skied. The disadvantage of using a lower cambered ski with longer contact area can not be overcome with “wet” structure and wax to the point that the skis are really good. This is especially the case in dirtier snow where the addition of a deeper structure to compensate for the increased suction (surface tension) created by having a longer contact area will only result in more dirt attaching itself to the ski base which makes the ski slow due to the added friction of having dirt on the base as well as the increased suction because the structure is filling up with dirt and the previously hydrophobic base material is covered with dirt and no longer hydrophobic.

In past years with different ski designs, many people including myself liked to err on the soft side, especially in the west where we get a lot of cold dry and slow snow. The current ski designs such as Rossignol need to be fitted properly and I personally lean toward the stiff side to ensure that the skis can function as intended.

Bottom line is that in order to have fast skis in all conditions, the skis need to be the right flex and design for the conditions and they need to fit the skier such that the contact area matches the intent of the ski design. If you put a 200 pound guy on a ski designed for a skier of 160 pounds, there will be an increase in contact area. Also, the more aggressively a skier skis, the more care needs to be taken to ensure that the skis are stiff enough to accommodate being suspended on the right length contact zones.

Looking at the chart above, you can see the different colors of the S1, S2, and S3 patterns. They match up with the Toko colors which makes sense because normally when you use one of those skis, you’d be waxing it with the color associated in the chart.

Structure is often the next most important factor, especially in the two extreme conditions which are cold, dry, slow snow and wet snow. In cold dry fast snow that is for example transformed, a more aggressive structure can be used with success. This is why I keep mentioning “slow”. A base finish that is not a “cold” grind (very smooth) will not run fast in cold, dry, and slow snow regardless of the flex of the ski and what wax is chosen. In very wet snow, a “cold” grind will not run fast even if the ski and wax are optimal.

All 3 factors in having fast skis need to be considered. Satisfying any one or even two factors will generally not yield fast skis if the third factor is in conflict with the conditions. Most times, the factor that is most in opposition to the conditions determines the speed of the skis, not the ones that are in agreement with it.

So, my recommendation is to consider skis from a macro level starting with ski selection (should not be too soft!), then structure, and then finally wax. It is not as complicated as it sounds if you are a passionate ski racer (ie, you are willing to invest financially as well as in physical preparation). Have an S1 ski with a fine structure that you generally will wax with Toko Blue waxes (need to wax with a softer wax periodically for the health of the base). Have an S2 ski with a universal or cold universal structure that you will more commonly wax with Toko Red waxes. And lastly have a pair of S3 skis with a warm grind on them that you will mostly wax with Toko Yellow waxes. This way you already have skis optimally suited for each general condition that have a structure that matches the condition where you would use them. Then finally wax is the “icing on the cake” and will then be able to really make the skis fast.

A ski racer could show up with all 3 of these skis prepared as described with no knowledge whatsoever of the conditions and basically always have good skis. With forecasting, it is possible to eliminate one or even two of the conditions associated with S1, S2, and S3 which makes it even easier and more convenient to have great skis. OK, now you know! Good luck and see you around!

Silver Star SuperTour Report

Cold fresh snow racing continued with the Super Tour/ Nor Am at Sovereign Lakes Nordic Center in British Columbia. We raced on a cold hard paraffin with Toko JetStream Red 2.0 powder. It was a bit surprising that the Red 2.0 tested and performed so well considering the single digit temperatures. The range of the JetStream 2.0 Toko powders is fantastic. We covered the powder with Blue 2.0 Helix.

The races were solid, but off the mark of where we really wanted to be. We are in the Methow Valley to train in prep for Nationals. We are feeling good and our preparation has us still ready to be on at Nationals.