The Madshus Redline 3.0 is no less than a small revolution three years in the making. There are huge changes under the hood on the new Redline 3.0 models headed for retailers this season. Madshus engineers explain what’s under the top coat of the all-new Redline 3.0 models.

The new Redline models are the result of intense product development, rigorous testing and an open-mindedness to question established methods and principles of ski construction and manufacturing, all in close communication with our top athletes and proven on the World Cup. Their feedback and experiences, requests and demands are carefully collected and thoroughly analyzed in order to develop the fastest, most reliable skis on the market.

What’s the difference between Redline 2.0 and Redline 3.0?

“There are three major factors determining the properties of a ski. The geometry of the ski, that is the thickness of the various sections of the ski, is one. The other is the flex and camber, and the third factor is the materials from which the skis are made. The geometry is the only factor we haven’t changed in the Redline 3.0 compared to the Redline 2.0. The flex and camber and the composition of the materials,” explains Bjørn Ivar Austrem, Technical Director (CTO) at Madshus and in charge of innovation and product development at the factory in Biri, Norway.

Story continues below

The all new groove

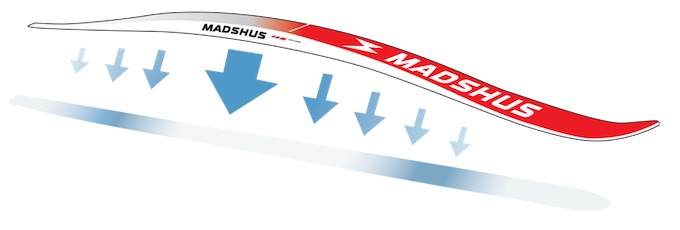

While there are huge changes to the inside of the ski in the new Redline 3.0, the design of the groove on the base of the ski is one of the most visible differences from previous models. The groove is shorter on all the new Redline 3.0, but different on all models depending on which conditions they are engineered for. On some models the groove is entirely eliminated on parts of the ski.

“The groove provides stability to the ski, but because our skis are very stable to start with, we are able to adjust the length of the groove depending on what kinds of conditions the ski is intended for. That allows us to engineer a ski with the optimal combination of liveliness and stability,” Austrem says.

He explains that the technology behind the groove design is based on principles of physics, but applied somewhat differently on skate skis and classic skis.

Classic skis for cold and dry snow, typically hard wax conditions, come with a groove only on the tail part of the ski. Classic skis for warmer and wetter conditions have grooves from tip to tail.

“The cold conditions models are designed with a short groove in order to increase the contact surface on cold, sharp snow crystals, and provide a better feel for the snow. At the same time, this construction also increases the surface area of the kickwax zone and provides better grip,” says Austrem, and continues:

“The warm conditions skis are engineered with a full groove in order to improve the glide in wet snow.”

There are two versions of the Redline 3.0 skate skis: The F2 for hard, fast conditions with a long groove, and the F3 for softer, slower snow with a short groove.

“A long groove on skate skis provide more stability as needed in hard, fast conditions, while a short groove provides optimal flow and allows the skier to adjust the direction of the ski more easily in softer, slower conditions,” Austrem says.

Story continues below

New flex profiles and more carbon

Moving on to the composition of materials in the new Redline 3.0, the biggest difference is that the new Redline 3.0 have significantly more carbon than previous models.

“We are always striving to find new and better materials that combined with solid geometries and correct flex and camber provide optimal glide and skiing experience, and for classic skis, reliable kick without compromising glide. On the Redline 3.0 models, we have added more carbon and developed a different layup of the carbon, resulting in both skate and classic skis that are livelier and more dynamic,” Austrem says.

The flex profiles are also reengineered, for both the skate and classic models. The skate skis come in two versions: one model with a stiffer flex for hard, fast conditons, and one with a softer flex for softer, slower conditions.

“With two different flex profiles, we can position the pressure points of the ski more accurately, which improves the properties of the ski. A ski with stiffer flex with a taller camber is more responsive and dynamic, but in softer conditions a ski with softer flex and a lower camber delivers more consistent response,” Austrem explains.

Story continues below

For the Redline 3.0 Classic skis, the flex and camber is adjusted to allow the ski to close more easily, depending on snow conditions. This provides a better use of the area in the kickwax zone, providing better grip without sacrificing glide. The flex and cambers on the classic skis are also engineered and adjusted for different snow conditions, and the Redline 3.0 classic come in two versions: One for cold conditions and one for warm conditions.

Redline 3.0 Cold has a slightly lower camber, less splay and medium long pressure points. Additionally, the Redline 3.0 Cold comes with a groove only on the tail end of the ski.

The Redline 3.0 Warm has a taller camber in order to make room for klister and soft waxes. The Redline 3.0 Warm also has more splay and the pressure points are somewhat shorter than on the Redline 3.0 Cold. The groove looks more traditional, runs through the kickwax zone and most of the length of the ski, although it is shorter than what has been conventional for classic skis.

Story continues below

Additionally, the classic ski is also available as a skin ski: The Redline 3.0 IntelliGrip. This ski comes with the same construction as the Redline 3.0 Classic Warm.

The double-pole classic ski Redline 3.0 DP is based on the construction from Redline 3.0 skate skis, with flex and properties specifically developed for long-haul double-poling in the classic tracks.

For junior skiers, Madshus features two Redline 3.0 models: One for skating and one for classic. These skis are based on the same technology and materials used in the World Cup models, but the Redline 3.0 junior skis are carefully modified and adjusted to fit the movement patterns and body size of younger athletes.

Isn’t it really expensive to develop skis in this way?

“Yes. But cost and budgets are no issue in the Redline engineering process. That’s the whole concept of the Redline models: We spare no effort or resources, not in the engineering process and product development, nor in the production,” Austrem concludes.

Inge Scheve

Inge is FasterSkier's international reporter, born and bred in Norway. A cross-country ski racer and mountain runner, she also dabbles on two wheels in the offseason. If it's steep and long, she loves it. Follow her on Twitter: @IngeScheve.