We live in an era where product lines are often dominated by several large companies. More and more, small companies are bought up by large corporations as soon as the small company shows an innovation or growth pattern which its lumbering competitor can’t duplicate. Consolidation, just shy of monopoly, is standard practice for many industries. Fortunately for skiers, this pattern hasn’t held true for cross-country ski wax. There are the big two—which is really the big one—but there are lots of small “mom and pop” wax companies putting out shockingly good products which are every bit as good, and sometimes better than their major competitors.

FasterSkier has previously taken an up close look at family run wax companies, when we profiled Rex, Fast Wax, and Rode. We now turn our eyes toward another family run operation, STAR Ski Wax. STAR is the definition of a family run business. STAR was founded in 1978 in the Italian town of Asiago by Roberto Mosele while he was employed in an Astrophysics laboratory where he was responsible for the design and implementation of a new digital orientation system for the observatories’ telescope. His occupation at the time as an observatory employee is how the company’s name was derived. Like many great ideas, STAR wax was the result of a dare taken on by Roberto Mosele over 45 years ago.

If there is something vaguely familiar about this story it’s probably because you might remember that Rode ski wax was also founded and manufactured in Asiago (population approximately 6,500). Whatever murky forces are at work in Asiago leading to the confluence of wax manufacturing is a mystery; perhaps it’s the cheese? But as wax consumers, it’s probably best to leave that puzzle to the ages and focus on the great products coming out of this small Italian town.

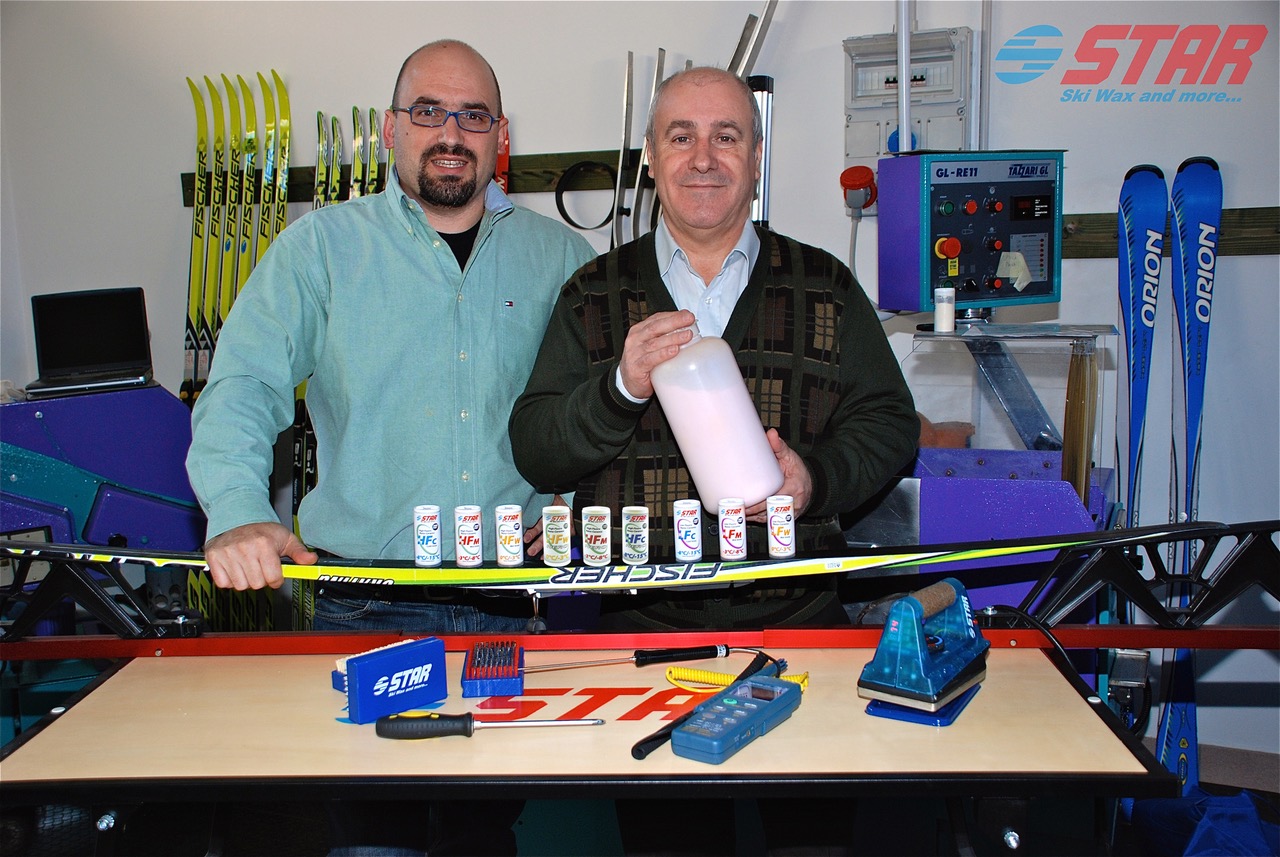

Davide Mosele the product manager of Star was kind enough to answer FasterSkier’s questions about the family wax business. Davide, 48 years old, is Roberto’s son, and is now responsible for the day to day operation of the business. His mother—Roberto’s wife— also works in the company along with Davide’s wife Cristina. With a grand total of six employees, it’s truly a family affair.

This interview has been edited for clarity and brevity.

FasterSkier: How was the company started and what was it like in the early days?

Davide Mosele: Star was founded in 1978 by Roberto (Davide’s father). Roberto was out cross-country skiing with friends, gliding through the snow-covered landscape. As they paused to wax their skis, one friend exclaimed, “Wow, it must be really difficult to make these products.” With a spark of determination in his eyes, Roberto declared, “I can do it!” What started as a lighthearted challenge among friends soon became a journey of passion and perseverance.

Over the next two years, Roberto poured his heart and soul into the project. It was far from easy, with countless trials and errors, but his unwavering dedication paid off. He eventually crafted an almost complete line of high-performing ski waxes. It was then that he began to dream of turning his new found expertise into a business.

At that time, Roberto was working for the Astrophysics Observatory of the University of Padova in Asiago. This connection to the stars inspired the name STAR for his burgeoning company.

Like many legendary startups, STAR began in the most humble of settings: a garage. As a child, I vividly remember his first laboratory being none other than my mother Donna’s kitchen. It was a whimsical sight, finding spaghetti pasta and ski wax sharing the same stove.

In those days, ski wax was often seen as a mystical product, but Roberto approached it with scientific rigor. What began as a garage project has now grown into two thriving buildings, and the playful bet with friends has evolved into a globally recognized company.

Today, STAR stands as a testament to Roberto’s vision and determination, a shining example of how a simple challenge can spark the creation of something extraordinary.

FasterSkier: As product manager, what is your role?

Davide Mosele: I deal with “products” at 360 degrees, from developing to testing them on snow. I follow races, talk with wax technicians, skiers, and share information. At the same time, I am present in the production area when we are “ cooking/ melting” product lots.

In a small family company we all know about all the things that are happening. Our coffee break in the morning is what a big company would call a “ general meeting” where many people, probably even located in different countries, have to make decisions and share information.

Roberto is still following production and new product development as well, and can share a lot of experience.

FasterSkier: Are there other family members involved?

Davide Mosele: Donna (Davide’s mother, and Roberto’s wife) has been working in the company in the sales and accounting department for 40 years. I have been working in the company since I was 18. I graduated in Engineering at Padova University in 2003 (which is the site of the observatory). My wife Cristina is managing the accounting office and sales for 15 years. My best friend Riccardo is also an important part of the company, taking care of all the mechanical department and running production machines.

FasterSkier: Do you see yourselves as underdogs battling the big two wax companies?

Davide Mosele: I believe that the size of a company is not always the key to success. In many industries, we often see large companies acquiring small start-ups that are able to innovate much faster.

STAR has carved out its space in the market thanks to the quality of our products and our ability to innovate and react quickly to market changes. While I respect the big companies as well as all other competitors, I do not feel like an underdog!

FasterSkier: What does your Research and Development (R & D) look like in terms of the skills and background of the people who work there and the size?

Davide Mosele: Research and Development (R&D) is the heart of our company; everything evolves around it. With over 40 years of experience, we approach each day with a curiosity that drives us to improve our products continually. We seek out anything that can help make skis faster.

Many of our products originate from specific customer requests—sometimes seemingly crazy ideas that turn into the perfect inspiration for a successful product.

I closely follow World Cup races, Ski Classics, and junior races. I am in contact with numerous professional ski technicians, and I gather all their insights to enhance our products. As a serviceman at these races, I know exactly which ingredients are used in our products. This firsthand knowledge helps me understand the effects of different ingredients on snow and enables us to respond quickly to any requests.

FasterSkier: What kind of seemingly crazy ideas do you get which lead to success?

Davide Mosele: Often, technicians find that a product works even in conditions for which it was not designed, or that when applied in a different way, the result seems better. Based on this information, I work on the formulation to optimize it for the new conditions of use. In other cases, the requirements are very specific. For example, last year we received many requests from Ski Classics teams. They needed a product that could last for their “long distances”… even 70-100 km. From this particular request, the “Durable” powder product was born, which was very successful. Later, they also asked us to develop the same product in liquid form! Durable Liquid proved to be very effective in extremely cold, abrasive, and dry snow conditions.

FasterSkier: Do you look to other industries to see what new compounds are available, or are you trying to invent new compounds?

Davide Mosele: As a product manager, I am always on the lookout for new material and innovative ideas. My curiosity, combined with my academic background, helps me understand the scientific advancements in materials.

I don’t just focus on new ingredients; I also explore how to achieve the best performance through different application methods. The same ingredients can perform differently when applied in various ways. For example, our fast-drying Next liquid, applied with a wool roller, has become a market benchmark. It’s not just about the chemistry but also about the application technique.

At STAR, we help our customers find simple yet highly effective methods to apply ski wax, ensuring optimal performance on the slopes.

FasterSkier: From the point of view of the wax industry, is the move away from fluoros a good thing? Has it been harder for small companies to adapt to this change?

Davide Mosele: When a new regulation comes into effect, it’s pointless to argue whether it is right or wrong; you just need to react and find a new solution. For those following the EU/EPA regulations, it was clear that fluorocarbons would have a short lifespan.

In 2019, I stopped considering fluorocarbons as an ingredient for ski wax and immediately began developing products using other material. It has been hard work, but also fascinating. This challenge opened up a new universe of opportunities, and I enjoy it!

FasterSkier: Are we close to having ski waxes without fluoros which are as good as fluorinated waxes in warm wet conditions?

Davide Mosele: Unfortunately, the chemical and physical characteristics—primarily the hydrophobicity and affinity to the ski base—of fluorocarbon waxes were exceptional, making them the “perfect” material.

This doesn’t mean we can’t have good working ski wax, but for now, it seems quite challenging to achieve the same performance offered by fluorinated ski waxes particularly in these specific conditions.

FasterSkier: What’s harder to develop, a really good kick wax or a really good glide wax?

Davide Mosele: Creating a good kick wax requires extensive experience and knowledge of raw materials. Achieving the best kick with the best speed is not easy; it’s a compromise. Since fluorocarbons are no longer available, developing a good glide wax has also become more challenging. We are exploring a large number of new ingredients/application methods, which consumes a lot of time and energy.

FasterSkier: Wax products seem to come and go and sometimes it seems like change just for change sake. But, it looks like smaller companies stick with proven products longer than larger manufactures. Is that perception accurate?

Davide Mosele: Changes are necessary whenever better solutions are found. Changing the packaging to make customers believe the product is new is not a good strategy. We aim to introduce new products to the market only when we are confident that they are better than their predecessors. Big companies can invest much more in marketing, in our company we believe that the best way to promote our products is to have satisfied customers, meaning we must have the “best” product and then the word will spread.

FasterSkier: Are we close to the point where people can throw away their wax irons for glide waxing? Do you think we’ll see a day soon when ski bases evolve to the point of never needing to be treated with glide wax?

Davide Mosele: We conduct extensive research on application methods. I believe the use of a waxing iron is essential for treating ski bases. Some liquid products deliver excellent results, and the use of wool rollers is becoming popular even for applying blocks. However, these products are a complement and do not replace the use of a waxing iron at a professional level.

For customers who do not compete, the use of liquid products and wool rollers is an excellent solution. Skis still need to be periodically waxed with an iron. Often, these customers turn to workshops or friends for hot waxing and use liquid products every time they go skiing, enjoying all the benefits of easy application while still achieving very fast skis.

FasterSkier: What’s the favorite product your company makes?

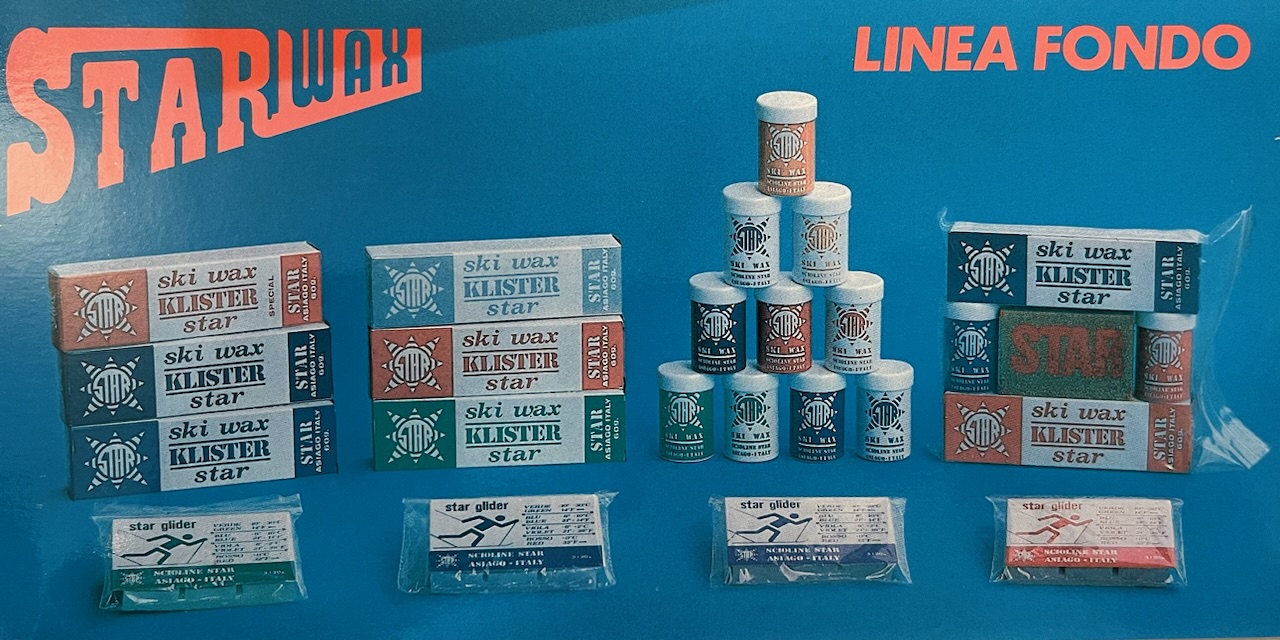

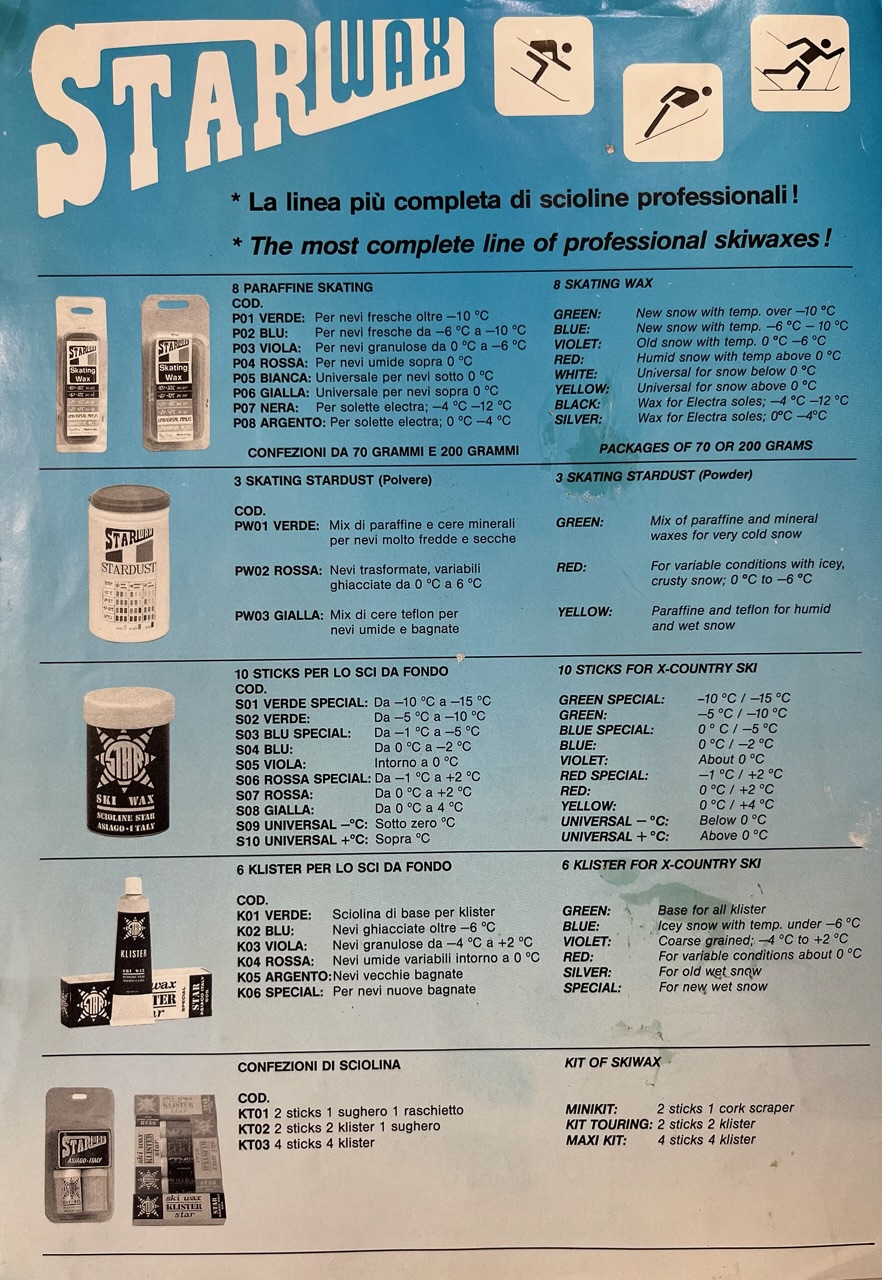

Davide Mosele: We love all our products and believe each one has special qualities that makes it unique. The fast-drying liquid products are very versatile and high-performing. Blocks applied with wool are widely used even in World Cup races and allow for easy layering of different products. The powders are perhaps the ones we cherish the most for sentimental value. In 1985, STAR introduced the first complete line of micronized powders to the market, long before fluorinated waxes. At that time, only blocks were used to wax skis. The easier and faster application with low waste was already a revolutionary idea. Of course during the years, raw materials have changed a lot … but still the powder aspect is our favorite.

We also have excellent kick waxes in our catalog that, especially in recent years, have won over many ski technicians. Many of these products were conceived together with a valuable collaboration in the United States. Ten years ago, we introduced 70mm rotary brushes to the market, which are becoming a standard not only for their size but also for the absolute quality of the materials used.

FasterSkier: You mention the pride of introducing micronized powders. Was that your father’s invention?

Davide Mosele: Yes, STAR was the first company to introduce a complete line of micronized powder products (emphasis added). The idea was to simplify the application process. Until then, ski waxes were based on very soft paraffins, and the waxing irons were not as efficient as they are now. Using harder products made it necessary to simplify the application… the micronized powder form was a good solution to these problems. Nothing is easy, but Roberto’s persistence made it possible for a small lab like his to create that formulation of waxes and additives in powder form.

FasterSkier: What is the hardest part about being in the ski wax business?

Davide Mosele: I love my job, so there is no hardest part. I feel lucky to do what I like!

FasterSkier: What’s the wildest idea your research department ever came up with that never got the go ahead?

Davide Mosele: Over the years, we have developed products that have never reached the public. Fortunately, as a company, we have decided never to release a product to the market before thoroughly testing it. We have a trial program where we are supplying product ideas to “professional people” who help in testing, knowing that some of these products may not turn into a valid ski wax proposal. The important thing is to never get discouraged and to learn from our mistakes.

FasterSkier: Are there any other products, other than wax, which you make which would surprise people?

David Mosele: Maybe people do not know that STAR waxing irons are produced in our factory in Asiago. It is 100 percent our project, and we are proud that it is highly appreciated in the market.

If you check our website, www.starwax.com, you will discover that we also produce a complete line of bike care products! This helps to keep us busy during the summer. We started producing bike care products 30 years ago, and our products are well known throughout Europe.

FasterSkier: Why did STAR get into bicycle maintenance equipment? Is there a lot of similarity between ski wax and bike products?

David Mosele: The idea is that skiers often cycle to train, so the brand remains in use even during the summer. Often, bicycle workshops become ski workshops in the winter. The chemistry used is not the same, but it is very similar.

FasterSkier: You are located in Asiago, Italy, which is also the home of Rode ski wax.

How did it come to be that Asiago is the home to two great wax companies?

Is there a big rivalry between the two companies?

David Mosele: Our relationship with Rode is the same as with all other companies in our industry. There is obviously rivalry, but at the same time, respect. I believe that all of us “small” ski wax producers share the same passion: making skis faster and helping athletes achieve their goals.

One funny thing is that whenever a team comes to Asiago to visit STAR, they end up visiting Rode as well—and vice versa. If you come to Asiago, you will certainly leave with the best ski waxes on the market!

FasterSkier thanks Davide Mosele for taking the time to share his family’s story and give us a glimpse into the life of a family run ski wax company.