The last several years have seen tumultuous changes in the ski waxing world. After the fluoro ban went into effect, manufacturers have been scrambling to bridge the performance gap between now prohibited fluorinated wax and non-fluoros. But it’s not just wax manufacturers who have been busy trying to figure out how to build a better mousetrap now that the most powerful weapon ever developed in the waxing arsenal has been sidelined.

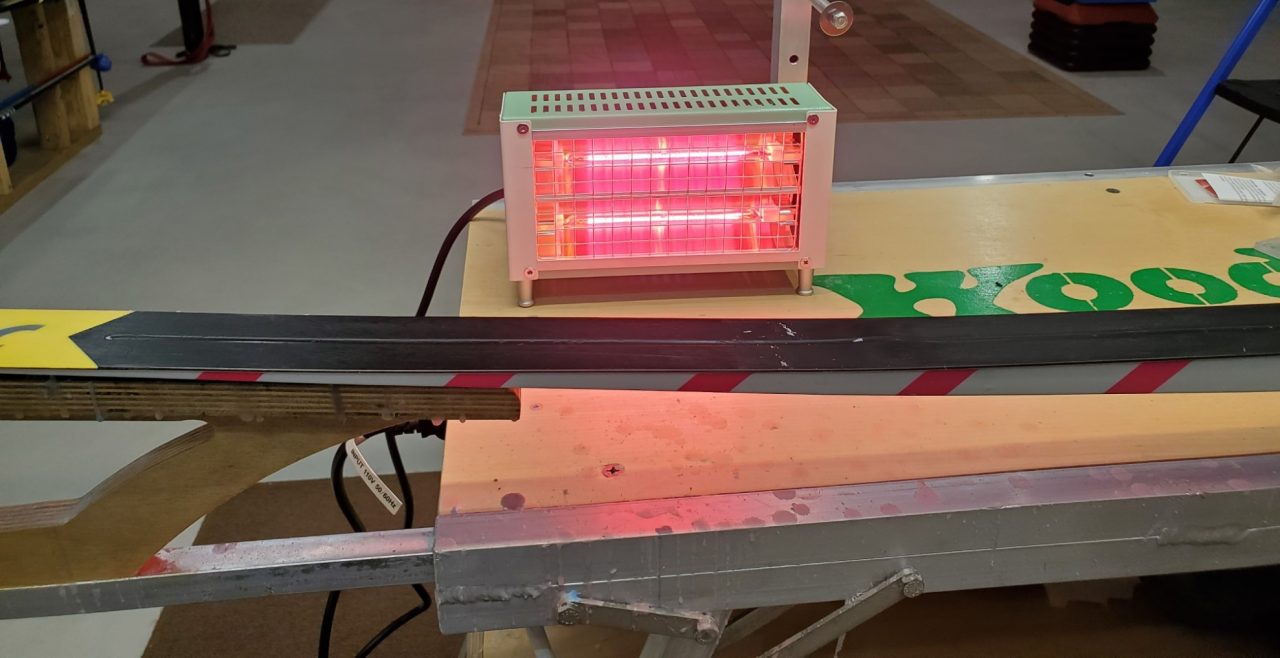

Wax technicians have also been experimenting with every application method under the sun to try and gain an advantage. They have been assessing innumerable variants such as—roto fleecing liquids, roto corking, slurry applications, and deep base penetration through infrared heat. Wait a minute; what was that last one? Applying wax using infrared heat? Yes, that’s the newest hot trend (a little pun intended) in wax application.

Everyone is familiar with infrared heating on some level. If you have ever stood outside an airport terminal or bus stop in the winter and felt the warmth from red heat lamps aimed at you, keeping you warm, or gobbled down some fast food that’s been sitting under a glowing red light, then you’ve experienced infrared heating. So, it’s not much of a stretch to ask, “would infrared heat melt ski wax?” We’re also in a time when infrared technology is having a bit of a star moment being touted as providing recovery benefits when exposed to human bodies, and infrared saunas are claiming benefits over traditional heating methods.

A company in Carbondale, Colorado now wants you to go infrared when waxing, and is selling a direct to consumer infrared waxer (you can’t accurately call it an iron) to replace your venerable waxing partner, the old iron. Mountain Flow is the company, and its founder and CEO, Peter Arlien wants to change the way you wax your skis, in every possible way. Not only is Mountain Flow selling an infrared waxer, but they also have a complete line of plant based glide waxes which do not contain petrochemicals.

Infrared wax application isn’t new, it has been around in Alpine ski shops for some time. Many Alpine shops have high tech commercially scaled infrared waxers which automatically travel the length of the ski on a moving arm and apply a deep coat of wax to your boards. The claims around infrared are intriguing and as it becomes more common place could it spell the end of the faithful and sometimes beloved waxing iron? For his part, Arlien isn’t seeking to destroy your friendly wax iron, but he does want everyone to be able to wax skis more; in a sustainable, efficient, and environmentally friendly method.

Originally from upstate New York, Arlien moved to Carbondale to have better skiing access. He doesn’t have an engineering or chemistry background to help with product development, but does have degrees in Neuroscience from Colby College and an MBA in Business Intelligence and Data Analytics from the University of Alaska. “I was and am a skier,” said Arlien. “That’s what got me interested, I did have a science background, but the wax was formulated from a skier’s perspective. I worked as a ski technician for years and waxed thousand of skis.” Arlien’s first saw infrared waxers in Alpine shops. Those are large expensive wall mounted units. “More and more shops are going in that direction because of the benefits of infrared; great base penetration, you use way less wax, and there’s no scraping or mess.”

Mountain Flow’s origin story includes an appearance by Arlien on the television show Shark Tank. In the show Arlien did strike a deal with the sharks, but at the end of the day, after the lawyers had finished, the deal didn’t go through.

Developing the infrared red waxer wasn’t hampered by Arlien’s lack of an engineering background. “Infrared technology isn’t new. We didn’t have to invent that. Basically, we just looked at what we wanted that wasn’t out there.” Arlien worked with infrared equipment manufacturers to develop prototypes of an infrared waxing device, which could often be a trying experience. Early on in the process Mountain Flow identified the number one manufacturer in the world in infrared technology and tasked them with meeting the company’s specifications. “They send you a sample and maybe it turns on, and that’s about it. But there’s about a million other things wrong with it. Then they send another one. It took us about two years to get a product we were happy with.”

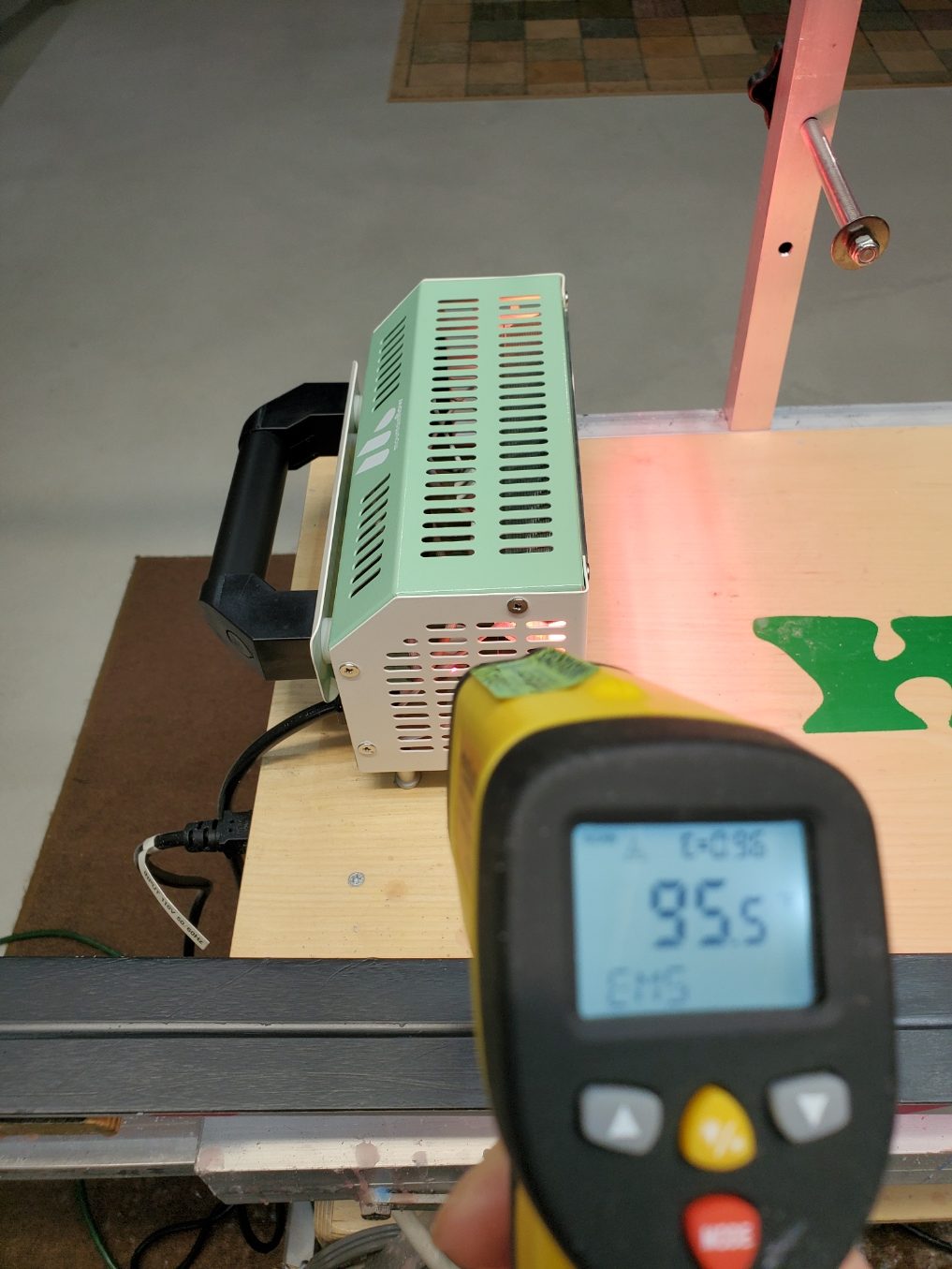

Arlien’s product kind of looks like a hollowed out iron with bulbs where the base would be. To use it, you hold the device a couple of inches above the ski and move it up and down the ski length just like an iron. But you never touch the ski base. When the waxer is turned on it comes up to temperature instantly, so there’s no waiting for it to warm up and there’s no variation in temperature as the waxer moves along the ski. You control the temperature by how close you hold the device to the ski base.

Arlien says infrared isn’t just for high volume waxers. “I think there’s huge opportunities in high performance waxing. You can do things you couldn’t do with a traditional wax iron. You can use it to speed up the application process, and I think you get better base penetration. Also, with the infrared waxer you can heat up the base with a liquid wax without damaging the ski.” To wax a ski when using conventional block wax, you crayon on a thin layer and then melt it in with the infrared waxer. Arlien says that the layer is so thin that it usually won’t require scraping, you can just brush it off. That’s touted as one of the big advantages. There are others. Everyone’s had the experience of working with super hard waxes like Start Green. When you scrape it after ironing— if you let it come to room temperature— the wax fractures and shatters, flying off the ski like a light bulb just exploding. This doesn’t happen with the infrared waxer. The residual wax layer is so thin that you can just brush out the ski and avoid the wax crackling or do some minimal scraping.

Then there’s the kick wax advantage. Klister and binder waxes can be heated in without touching the ski. When using a conventional iron with klister and other kick zone waxes, there’s always the problem of cleaning the iron after applying the kick zone wax to avoid getting contaminated kick wax into the glide zone. You either have to very thoroughly clean the iron to avoid later contamination, or the more obsessive-compulsive among us will use a dedicated kick wax iron. But it’s a completely different process with the infrared waxer. Since the waxer never touches the ski, there’s no mess to have to deal with.

Arlien also sees applications for recreational skiers who are just interested in having a more enjoyable skiing experience. “You can hot wax the fish scales of a Nordic ski. This would be instead of using anti-icing treatments. You’re enhancing glide and getting anti-icing from the wax, but you’re putting on such a thin layer that you’re not clogging the structure of the fish scales. It’s such a thin layer you don’t loose kick. I then do a reverse brush, going tail to tip, to remove the residue.”

Business for the infrared waxers has been brisk. “So far in September, we’ve almost outsold our entire winter last year. People love the concept and how easy it is to use. Typically, with ski wax when you make the process easier, there’s a tradeoff. With the infrared, it’s quick and easy, and you’re actually getting more performance out of the wax.”

There’s no need to worry about the device’s longevity. “The bulbs are gold halogen and are supposed to last for 10,000 hours, but they can be replaced if needed. The waxer comes with a two year warranty.”

There are a couple of basic safety precautions to employ when using the infrared waxer. Since it projects heat, don’t leave it on pointed at anything combustible, and don’t point it at wax sitting on your bench, since it could melt it. The device might help keep your work area a little warmer, or even potentially heat up a cup of coffee, but as Arlien points out, you don’t have to worry about it giving you a sunburn. “Infrared is on the opposite end of the light spectrum from ultraviolet, and it’s ultraviolet which gives you a tan.” But you still shouldn’t point it at skin since it could make it hot. This is all easy to deal with since the instructions state to turn the waxer off when you set it down. Since there’s no warmup time when you turn it on, there’s no reason not to turn it off.

Arlien doesn’t just want to change the way you wax; he also wants to change what you wax with. After spending years working in a ski shop, he was tired of working with wax derived from petrochemicals. His solution was to invent a plant based wax. “Wax is petroleum, and whatever you put on your skis goes into the environment, directly into the snowpack, and into our watershed. That didn’t feel great. I was convinced there were other solutions. So, I dug into tribology (the science and technology of interacting surfaces in relative motion) articles to see what plant based substances would work. I just kept iterating … ski all day, go home and kept iterating and getting better and better results.” The process took about two years. The wax contains no petrochemicals. Arlien has tested his product against other non-fluoro waxes and claims it compares favorably, and that the durability is as good or better. “The first year we went to the Birkie we brought a team of seven skiers, and we had four top 15 finishes, and people were saying they were coming across the lake (towards the end of the race) and the wax was flying.” Most of the waxes contain products which are already used on the market for natural beauty products and that’s the source for most of the raw materials.

Arlien says that the easiest way to purchase the infrared waxer is through him directly at Mountain Flow. The infrared waxer sells for $249.95 and comes with an elegant carrying case.

FasterSkier appreciates the support of our new partner MountainFLOW this season. As a celebration of this new relationship MountainFLOW is offering the FasterSkier community a complementary bottle of whiskey from the Steamboat, CO based Mythology Distillery* with the purchase of an Infrared Waxer and a 10% discount on all additional MountainFLOW purchases — to take advantage of this opportunity use promo code fasterskier at checkout.

*Purchaser must be 21-years-old and live in a state Mythology Distillery can ship too.