GLIDING is a niche science journal spearheaded by Matthias Scherge and a cohort of advisors. Scherge the Fraunhofer MicroTribology Center in Germany. The research institute specializes in industrial lubricants and is assisting the International Ski Federation (FIS) with their fluoro free guidelines.

Scherge’s side project, GLIDING, as the name suggests, presents findings related to gliding on snow – which means analyzing the interplay of wax, base structure, snow, and other micro-variables impacting ski glide performance.

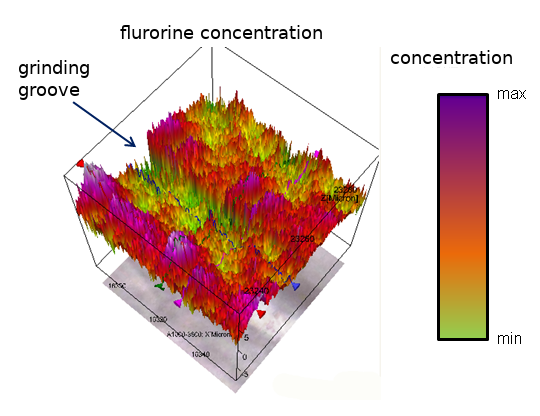

GLIDING recently published a paper analyzing the complexities of ski bases and where, in fact, wax bonds on a ground ski base. The authors also compare the thickness of the residual wax layer (post scrape and brush) between powders and sprays. You can find a brief abstract below and the full-length article here.

Abstract:

“With physical/chemical surface analytics the layer thickness of wax was measured. The measurements prove that wax as block or powder penetrates the ski base only a few 100 nm and as spray only a few 10 nm. The wax does not use any pores in the ski base but entangles with the molecules of the polymer to form a compact sliding layer. The durability of this layer depends primarily on its thickness, but also on factors such as snow temperature, snow grain shape and the quality of the polymer from which the ski base is made.”

Introduction:

“Almost every skier knows the stories that a new ski has to be waxed and scraped several times before it runs well. It is also well known that the ski has to be waxed thickly before the summer break so that it does not turn gray next winter. The base of the ski is usually made of high-density polyethylene (HDPE) or, in the case of competition skis, ultra-high molecular weight polyethylene (UHMWPE). These polymers have different qualities and may also have been produced using different processes, so that the bases degrade to different degrees, i.e. turn gray. High-quality bases show hardly any graying and remain stable over long periods of time. If you have a ski that is prone to graying, multiple waxing and scraping helps, as these steps remove the degraded skin. If the degradation is thick, a steel blade can be used instead of the plastic blade. Wax covers the ski base and prevents the polymer from coming into contact with oxygen. When the ski is worn, it is rubbed by the snow grains, a process that generates local heat. The following article explains to what extent wax offers protection against graying, how long this condition lasts and how it can be improved.”

Matthias Scherge has been studying the basics of gliding on ice and snow for more than ten years. He heads the MicroTribology Center, a joint institution of Fraunhofer and the Karlsruhe Institute of Technology, where he teaches tribology as a professor. Tribology is the science of friction, wear and lubrication and deals, among other things, with the gliding behavior of skis. Since 2012, Scherge has been advising the Nordic Paraski Team Germany and leads Team Snowstorm, an efficient network of companies and academic partners supporting athletes and ambitious winter sports enthusiasts: http://team-snowstorm.de/index.html