All in the family

People often lament the demise of small artisanal crafted goods. The dominance of huge retailers and manufacturers is often viewed as something between a sign of the approaching apocalypse, and proof of various conspiracy theories. In many industries, when you think of the absolute pinnacle of quality and performance, smaller companies often come to mind: Ferrari for cars, Shinola for personal goods, and, (showing my personal bias) Jenny’s for ice cream. As a reaction to huge retailers, there’s been a growing movement to support small businesses, especially family-run businesses.

The ski wax market may appear to be dominated by the big two—Toko and Swix—who are owned by a multinational conglomerate. Unequivocally, both of these companies make great waxes, and many skiers are perfectly happy with Swix and Toko; that’s totally fine. But there are great alternatives to the big two, other companies offering a different view of the waxing world and producing products on a different scale. This broader—perhaps more nuanced—wax world is epitomized by small family companies.

The ski wax industry may seem like a David versus Goliath competition, but the owners of family-run wax companies don’t see it that way, feeling that they stack up to—and are as good as, or better than—anyone in the industry.

Ski wax is a product used anywhere that snow falls, so FasterSkier interviewed representatives of family-run ski wax companies from around the world. The three companies interviewed represent diverse geography, but they have two things in common: a passion to make really fast ski wax, and they are run by families. We interviewed representatives from Rode, Rex, and Fast Wax.

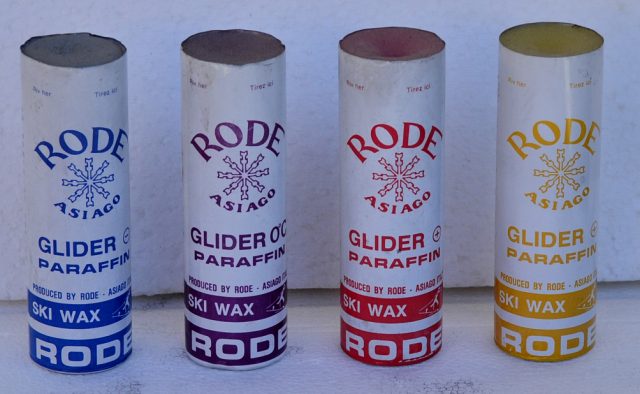

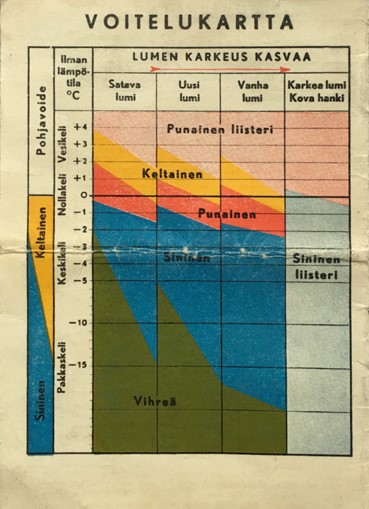

Rode is based in Asiago, Italy. Asiago is the home of the eponymous cheese, but for the ski crowd, the more meaningful association is with Rode ski wax. From Rode, FasterSkier interviewed Simone Carli, grandson of founder Rizzieri Rodeghiro. Rode is run by Rodeghiro’s daughter, Roberta, and the founders’ grandchildren. Rode’s founder won 7 Italian titles and competed in the 1948 Olympics along with being the national team coach. He began making wax in the 1930s, and the name of the company is the founder’s nickname: “Rode.”

Across the European continent in Hartola, Finland, resides another family run wax business: Rex ski wax. Rex ski wax CEO, Antti Peltonon was kind enough to chat about wax issues. Antii is the grandson of Toivo Peltonen who started Peltonen ski company in 1945. Toivo Peltonen started making skis after he returned home from World War II. Necessity was the mother of invention for making skis for Peltonen. He had started out making ski wax, but due to post war shortages he couldn’t get the raw material, and switched to making skis. But things came full circle when the Peltonen family purchased Rex wax outright in 2002 and they were back in the wax business. Rex has been run by a member of the Peltonen family since they purchased the company. Rex is owned by Antti and his siblings Leena and Heikki. Antti set the record straight that Rex and Peltonen skis do not share ownership, which is a common misunderstanding in the ski world.

Moving across the ocean to Bozeman, Montana you’ll find Fast Wax. From Fast Wax, we submitted questions to Casey Kirt who manages the day to day company operations. Fast Wax was founded in 1996 by Dan and Rosie Meyer who are retired. The company is now run by Casey Kirt, along with Kirt’s wife and daughter.

All three companies are family-run operations. All three were extremely generous to spend time with FasterSkier to discuss their operations, and what it’s like to run a family-owned wax business. Running any family business is a struggle, but running a family run ski wax company presents many unique challenges and interesting stories.

None of the three companies give even a hint of being an underdog. From their viewpoint, smaller is better. For them, it’s not the size of the dog in the fight; it’s the size of the fight in the dog!

These interviews have been edited for brevity and clarity:

FasterSkier: Do you see yourselves as underdogs battling the big two?

Rex: We don’t really think of the size of the companies we compete against; the products are more important. Like us, most of the well-known ski wax companies have been around for decades and have found their position on the market and have their following. The Finnish market is one of the biggest ski wax markets, and it is dominated by three local ski wax brands Rex, Vauhti, and Start. In the Finnish market, the multinational conglomerate is the underdog, so it depends on where you are looking at. I think many people want to support smaller family businesses though, which is nice. In the end, it boils down to which products perform well and which do not, regardless of the brand. So the key to successfully competing in the market against all companies regardless of their size is to make better products.

Rode: If we look at the global market share, we can see ourselves as a small company fighting against the big ones, but if we look at competitions [racing] only, which is where we put our efforts, we are sure that we are not inferior to big companies. Those who prepare the skis of top athletes can confirm this.

Fast Wax: There is no point going head-to-head; we are blazing a new trail. With the focus moving to an earth friendly perspective. We kill the European brands in carbon footprint. If people truly want to be eco-friendly, then they need to take the entire supply chain into account.

Just like in the classical allusion of David and Goliath, being smaller presents certain advantages. Once again, each company was certain in their ability to deliver things which the larger companies can’t.

FasterSkier: Are you able to use you smaller size to your advantage?

Rode: Certainly, our small size allows us to have a more direct relationship with our customer, whether it is a high-level athlete, a retailer, or others. This allows us to look closely at their needs and understand the issues right away and act quickly to find the best solution, both regarding the products and the services we offer. This process, in multinational companies, is much slower.

Rex: As a small company, we can bring new products onto the market quickly, and our “Racing Service” collection has been a good example of that. On the racing side of the business, it’s an advantage when the main chemist is also doing testing and talking and having a couple of beers with the team servicemen. But in general, our hierarchy is low, and we work as a team with our engineer, sales guys, and production, and can plan and sort out things easily and quickly.

Fast Wax: Yes we can create, package, and distribute new products in months.

The idea of chemist and service technician discussing wax performance over beers is the kind of low-key idyllic image that many people think of when they imagine small high-quality manufacturers. It is also a completely different type of corporate culture than one would expect to find in larger competitors. But do these appealing aspects present restrictions when it comes to developing new products?

Each company has unique methods to develop new products. They go beyond their own company’s walls and consult with outside resources to develop new compounds. Each does it a little differently, but they are resourceful in finding ways to get results.

FasterSkier: What does your Research and Development (R & D) look like?

REX: I think of our R&D department as a network that consists of our employees, our key suppliers, and our R&D partners, which are mostly national, XC, and Biathlon teams we work with. It’s an international network where each one is an expert in their area. It’s not like we are bookish chemists that work in our hermetic chamber and then come out with something. There is lots of cumulated knowledge and a vast catalog of raw materials in our company after making ski waxes continuously for 70 years, but we are always actively looking for new compounds and implementing them into our products. Testing on snow in all kinds of conditions is really important.

Rode: Part of the products that are developed are designed by us according to our own studies, while others come from the collaboration with our chemical suppliers, who help us in finding the right solutions. From the tests in laboratory, we are able to study certain characteristics of the products, but then we always have to do practical tests on snow, which do not always confirm what we see in laboratory. For this you need experience, it is also thanks to this that we manage to keep up with bigger companies.

Fast Wax: I utilize chemical engineering students from Montana State University looking for real world experience. We work on a few topics then their research notes get handed down to the next guy. We take known products and alter them to generate a test wax. We then use bench tools to evaluate the result; melt-point, hardness, side contact angle, then move on to usage testing. Does it go onto the ski well, does the product dry out or become unusable due to mishandling? Simultaneously we are going into the back country and using this on skis while documenting the snow and metrological conditions.

FasterSkier: Do you look to other industries to see what new compounds are available?

Fast Wax: The friction challenges that skiers face is not exclusive to them. There are many industries that we follow to see what the hot new additive is.

Rode: We try to keep up to date with what is being studied and used in other industries to see if there is something that can be useful to us. The chemical industry does not produce anything specifically for waxes because the volume of raw material that is used in our field is small. All the compounds used in ski waxes are mainly made and used in other fields. The first fluorocarbons used in waxes were actually made to improve the smoothness of boats on water.

Rex: Compared to other industries, the ski wax industry is small, and many of the raw materials are “borrowed” from somewhere else. But we also have some ingredients that have been designed specifically for us. Fluoros were developed for other industries long before they were used in ski waxes, and the ski wax industry has always been a minor user of those compounds.

Innovation is difficult. Innovation imposed from the outside is even more difficult. In the last several years wax companies have faced the additional challenge of complying with government and federation imposed changes to their products. Regardless of whether these changes are viewed as important environmental protections or overreaching window dressing, they have created real challenges for the way wax companies do business.

FasterSkier: From the point of view of the wax industry, is the move away from fluoros a good thing?

Rex: In general, moving away from fluoros and all possible non-sustainable compounds is a good thing. It is also good for the wax industry. The governing bodies in our sport don’t make it easy though! It would be way easier to just deal with the EU’s REACH and USA’s EPA regulations. The politics around the fluoro ban are hurting the sport more than they are helping the environment and safety. Fluorinated substances will eventually be banned by the EU and EPA anyway, and we are OK with that. Why make it more difficult especially when there is no reliable, easy, and economical way to make sure everyone is obeying the rules.

Fast Wax: If you had $450,000 of raw fluoros sitting in your warehouse I would say that would hurt. What do you do with that now? Now you [also] have to pay to dispose [of them]?

Rode: It’s still a question mark since there’s not an effective control system to prevent the use of fluorine. Without controls, you cannot ban the use of something that gives performance benefits. Of course, in certain markets it is banned from sale, but in most of the world the new generation fluorinated waxes can be sold without problems. We must always consider that most of the production of fluorinated compounds is done for other industries, and the wax industry represents a low percentage.

FasterSkier: Has it been harder for small companies to adapt to this change and how did you go about making the change?

Rode: We believe that the uncertainty related to the use of fluorine has brought us advantages. Our company was not well known for glide waxes even if we’ve had good products for a few years now. We have always been known for kick waxes. The fact that everyone is now looking for the best fluor-free products has meant that our glide products have also been tried, and many people have seen that they are worth it. Moreover, in the past few years we kept trying and working on fluorine when other companies eliminated it or stopped researching. We’re happy we did it because we had very good results, especially in world cup races, where our products are being used more and more. We are still putting most of our efforts into finding alternatives to fluorinated products, either by trying completely different solutions from what we’ve seen so far, or by modifying non-fluorinated products we were already working with.

Rex: Fluorinated waxes used to rely only on fluoros to make them fast, but the latest generation of waxes also

feature other compounds that enhance their performance. For example, the R&D of our latest generation of HF waxes was mostly done without any fluorinated compounds in them, because that way we could notice other improvements better. That’s when we also discovered our first-generation N-Kinetic additives. The name N-Kinetic is a broader word for all the alternative technologies we use to substitute fluorinated compounds. So going fluoro-free did not mean we had to go back to the early 80s technology-wise, but more like just leaving one ingredient off from a mix of several other compounds. It’s a big change for the industry but also a possibility for companies regardless of their size, to come up with products that stand out from the competition and gain market share.

Good glide wax must do only one thing well, go fast for a long time. Whereas the properties of good kick wax are simultaneously different. It has to be sticky enough to provide good kick but be smooth enough to not ice and to allow for glide. This internal contradiction seems like some type of logic puzzle. Is it really that hard to figure out how to make a wax which simultaneously kicks and glides? Those little tins of kick wax turn out to be trickier to make than you might think.

FasterSkier: What’s harder to develop, a really good kick wax or a really good glide wax?

Rode: I think it is more difficult to develop kick waxes as you have to do many tests in the field, whereas with glide waxes you can perform laboratory tests more easily.

Rex: I would say developing a good kick wax is more complicated. Kick properties can’t be tested like glide waxes can be tested in glide-out tests. In addition to grip, the glide properties of grip waxes are important, especially in racing.

Fast Wax: We are in the second year of development of a kick wax. If we can find a market for it and it is as good or better than what is on the market, we would release it.

FasterSkier: Wax products seem to come and go. Sometimes there’s an impression that changes are made just for change’s sake. But there appears to be a trend that the smaller companies stick with proven products longer than larger manufacturers. Is that perception accurate?

Rex: We like to keep our line-up stable and not invent new product lines if they don’t offer anything significant. That way the line-up stays easier for people to understand because there is not a new series coming every year. But another thing is silent upgrades we make to products for one reason or another. For example, in 2019 we updated the standard glide wax series with our Power Polymers wax recipe that we launched first with our HF series. Innovations trickle down in the product line-up like that. Ski bases have changed in the last couple of decades, so waxes will have to change too, to continue delivering good performance. With that update, our beloved classic wax series was updated to meet the requirements set by modern ski base materials. Durability and speed were enhanced also. But what stays is that you can always trust our Rex blue glide wax!

Rode: If a wax is good and athletes still use it and win with it in world cup races, then we don’t see why it has to be changed. Of course, we always try to improve, but if a product has been on the market for many years this suggests it’s safe and successful. Our most famous products, such as Blue Super and Viola multigrade kick wax, or Rossa and Multigrade klister, have had constant developments in the past even if the names of the products were not changed. Every 2 to 5 years small steps were made in formulations, but they were gradual. They have remained unchanged in the past few years, but we always try to make some improvements. Keeping the product name has made customers loyal.

FasterSkier: Are we close to the point where people can throw away their wax irons for glide wax? Do you think we’ll see a day soon when ski bases evolve to the point of never needing to be treated with glide wax?

Rex: Another big change is the rise of liquid gliders. The change from “quick waxes” that were looked upon by enthusiasts[recreational skiers], to products whose properties break the boundaries and performance limits of previous hot waxes. As for throwing away the waxing iron, it depends. You always need hot waxing to lift up the hand structure, and those are used in racing a lot. And in racing use, it’s way faster to hot wax a ski than use a liquid glider and wait for it to dry for 20 minutes minimum. But for the average skier, waxing has never been easier. Aside from liquid gliders, I think the whole waxing culture has changed. People have moved away from hot waxing a couple of times every season, to using Rex Glide Cleaner after every ski to ensure their skis stay clean and fast, and then easily add the wax of the day on top of it. Wax more often, wax easier and keep the bases clean and fast all the time with minimal effort.

Fast Wax: That fad [moving to waxless skis] comes around about every 8-10 years… the question of fighting friction is not a one size fits all. To maximize the reduction of friction you have to address all of the friction sources not just one.

Rode: Liquid waxes have become popular lately, mainly because almost every ski wax company put great effort in studying and developing them, and they are very good now. However, you cannot treat skis only with liquid waxes, the ski base will suffer over time. The use of iron is still necessary now if you want to maintain the ski base in a good shape. [Regarding waxless skis] I don’t know, it could be, but base treatments still cost a lot and don’t justify the benefits. You also have to consider that bases are subject to wear and tear.

Rex: I’m not seeing that [waxless skis] happening soon. If that were to happen, I think a good analogy would be skin skis. People got rid of grip waxes, but skis still require cleaning agents and conditioners to keep them working well. Skin ski products are a lot bigger product segment for us than grip waxes, and it suits us well.

FasterSkier: What’s the favorite product your company makes:

Rode: I say Klister Rossa because it is one of the first products that was developed. It’s always had good results and we still sell a lot of it today. It is perhaps the flagship of the company. There have been minimal updates of the formula over the years, but it’s very simple and easy to make, much more than all the other products. And it’s amazing how many have tried to imitate it without success.

Rex: Glide Cleaner and Blue spray gliders. With grip waxes, my favorites are Tar Universal and Gold Klister. Nothing beats classic skiing in klister conditions when the tracks are ultra-fast and you can trust the grip 100%. Also worth a mention is our upcoming hot wax for bicycle chains!

Fast Wax: Probably HSX as it has the has the greenest of the green additives in its formula. This is what 1000’s of recreational skiers use each season. All of these people leave no trace when they are done skiing.

FasterSkier: What’s the wildest idea your R&D department ever came up with that never got the go ahead?

Rode: A few crazy ideas over the years have been there. We believe it’s not always easy to test whether an idea is good or bad, but you’ll never know until you try! You should always do some testing, even if you are almost sure there will be a bad result. Even so, it’s important for experience and the development of other ideas.

Fast Wax: We shaved wax on to the ski base then sprinkled it with gunpowder. We wanted to make a flash wax, sprinkle it on light it, and have the heat generated melt the wax and save you from ironing it in. There was way too much junk left over from the gunpowder that pushed this into the trash pile pretty quick. (Editorial note: Do not try adding gunpowder to your wax, but that is some crazy out of the box thinking!)

Rex: If the wild idea is a good one, it most likely ends up in production. If it does not end up in production, it was a actually bad idea, to begin with, not a wild one.

FasterSkier: Are there any other products, other than wax which you make which would surprise people?

Fast Wax: A lot of ski brushes “Think oval with a strap” are horse brushes first, rebranded for skiers.

Rex: Over the years, we have made: Wax for dance floors, wax for diving suit zippers, wax for tire installation, wax for revolvers. Mustache wax would be nice, but we found out there is already Rex Mustache Wax on the market. Bummer!

Rode: We’re working on something, you’ll see!

FasterSkier: Thank you to all of the representatives for taking so much time out of their busy days to talk about their great companies.